Guide catheter fusing/reflow machine with an 8-station moving oven and programmable catheter length.

Infusion pump controller and pressure monitor for up to 6 simultaneous independent infusion therapies. Programmable infusion profile protocols. The pressure trace provides real-time therapy performance feedback and diagnostic to the surgeon.

Automation of an existing 30,000Volt Transformer Potting process and equipment. Vacuum, proximity, position and other sensors along with hydraulic actuators, RFID transceivers and a PLC were integrated to automate the process which ran unmanned once product molds were staged on the input conveyor. The potted transformers were stacked on an output conveyor emptied once per 8-hour shift.

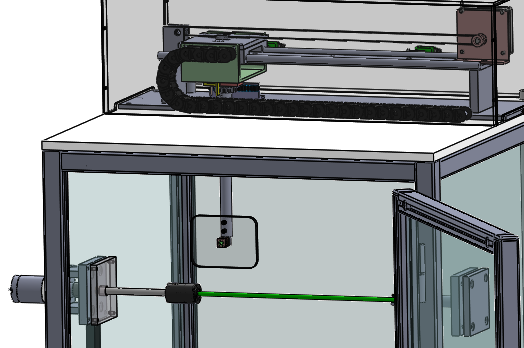

Inline expansion of FEP tubing to produce medical heat shrink tubing.

MRI guided drug infusion.

High voltage reciprocating stream spray onto a rotating grounded target.

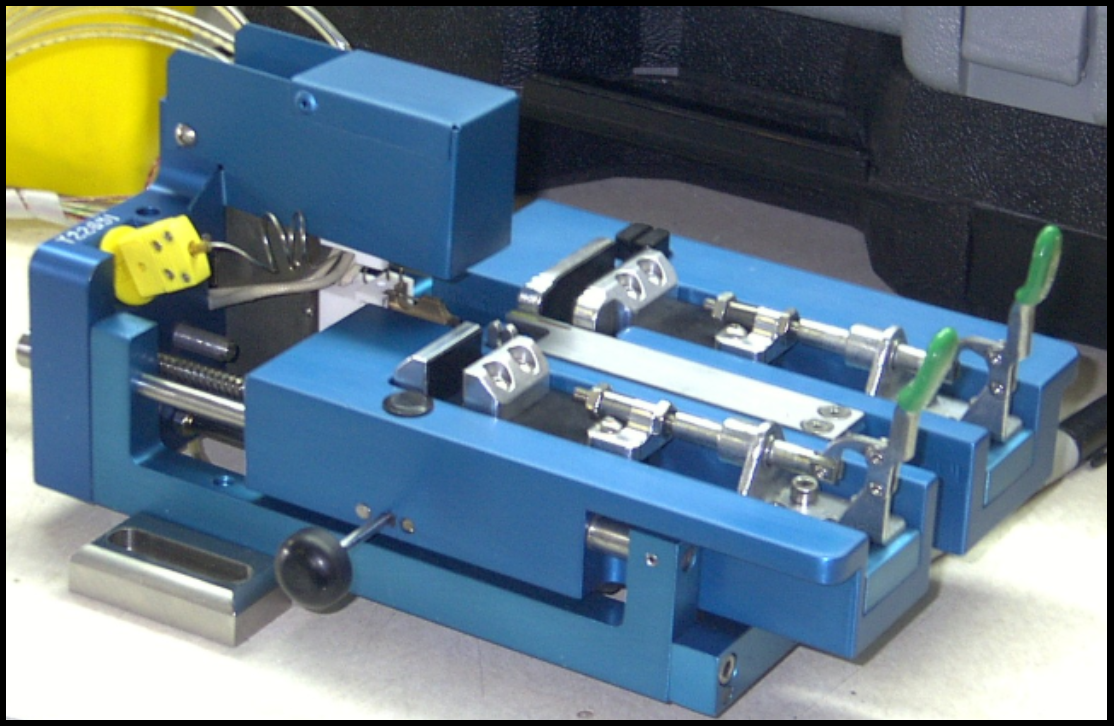

Angioplasty balloon and catheter assembly, alignment, inspection and welding station. This single fixture replaced three separate workstations.

That's why Fortune 1000 companies and world class hospitals trust ERG for their most complex projects.