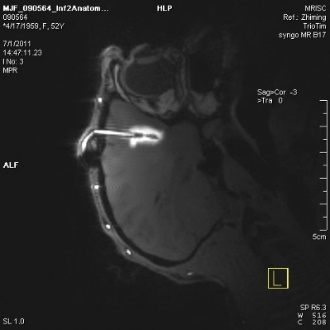

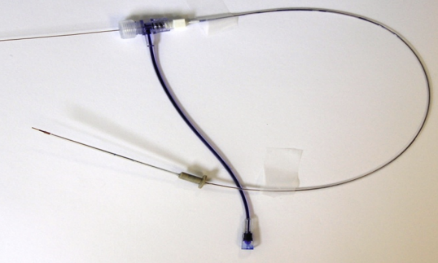

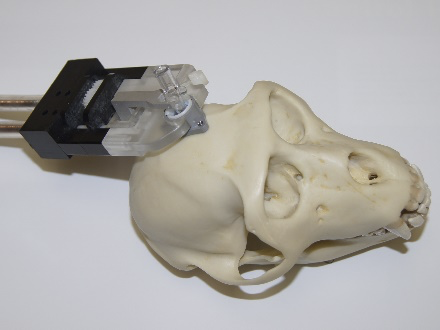

Over several years we worked with ERG to develop catheters and sensors to monitor the infusion of therapeutic compounds into the brains of non-human primates. The material supplied and the interaction with ERG personnel were always first rate. We would not have been able to do the complex work we wanted to do without their timely support. We would recommend them to anyone as a partner in their work. We needed help with the design and manufacture of a multiport catheter suitable for use in a rhesus monkey. The available catheters were designed for use in humans and we needed to have one developed for use in the smaller animal brain. We still wanted it to be a multiport version to reduce the chance of port obstruction. Secondly, we needed to develop a method to inject small amounts of an agent into the catheter repeatedly after the catheter was implanted. This required the development of a non-magnetic “Y” connector and stoppers to plug the access port until the day of infusion.

Since 2012 ERG supplies our department with custom made brain infusion catheters, infusion pressure transducers, and ERG developed pressure recording software. Throughout these years we have conducted effective and reliable dialogue with ERG to fulfill our custom needs, and the company influenced our success in the image guided surgery on non-human primates tremendously, especially in the targeting and the convection enhanced delivery of the infusate. ERG is known for developing forward-looking technology and delivers easy and smart solutions.

"Partnering with ERG for the development of intraoperative MRI equipment for intracerebral delivery has been critical to our team success. Timely and responsive to our needs, ERG has proven to be a reliable, knowledgeable resource to help transform crazy ideas into reality."

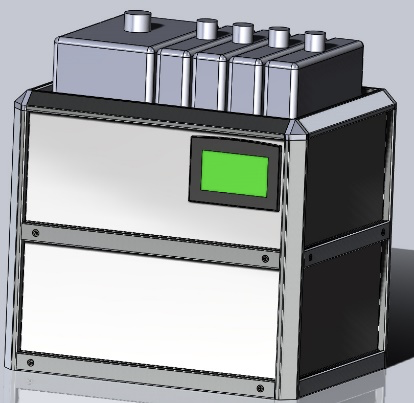

We have been working with Engineering Resources Group on the development of a prototype device for automating the comet assay (single cell gel electrophoresis). From the outset, the experience has been outstanding. Critically, communication was clear, responses rapid, and a high level of attention was used throughout – despite three-way communications between the various parties. We quickly developed a strong research proposal, that we proceeded to polish. We look forward to continuing to work with ERG on our proof-of-principle device.

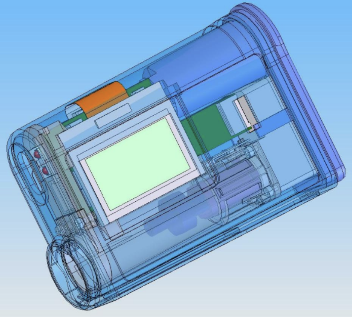

Chris Ross and ERG were an excellent development partner. We hope to continue to work with ERG for years to come. They took our concept and turned it into an engineering design and manufactured prototypes. As a result, we have progressed from idea to a physical product we can now test and demonstrate. ERG engineers were fast, conscientious and genuinely interested in a partnership that would lead to a successful solution. We will use them again without question.

We needed help with injection molding parts of a thoracic aortic aneurysm delivery system. The major benefit was using Chris Ross' extensive knowledge of injection molding tooling and plastics of medical devices. Engage Chris and his company as a reliable vendor and source of excellent engineering services that can support all aspects of product development.

We needed help to solve the problem of drug delivery to the brain. Our team benefitted by having a contentious partner in Engineering Resources to get solutions for HW and SW done efficiently. Often solutions were presented proactively by Chris Ross and Engineering Resources. Engineering Resources is a fantastic group of problem solvers and will work with you to provide both engineering and managerial solutions. My 6 years of working with them have been nothing but positive. I highly recommend them.

Early on in the development of the Bolton medical manufacturing line we needed tooling assistance with a support member bond tool. We gave ERG our requirements for bonding, shielding and capacity. ERG provided a fully functional tool that met all our needs and requirements and is still in use today over 8 years later. We benefited by having Chris Ross come in to the facility and see exactly what was needed to develop the new tool. ERG has great quality and is fully involved from beginning to end. They are worth the money.

Nipro Diabetes Systems needed help with scaling up life-sustaining Medical Devices for Manufacturability (including many plastic injection molded components) as well as significant Re-engineering to better meet end-user needs. Nipro benefitted significantly from working with Engineering Resources Group. Chris and his company helped us solve the most challenging technical issue I've have faced in over 15 years of Product Development. Typically, Medical Devices are designed and developed strategically from the ground up based on very defined Product Specifications. In this case, we had the major challenge of re-engineering an existing Medical Device to meet a new challenging Marketing Requirement. This change was tantamount to making a car have the beneficial characteristics of a boat. Through collaboration with ERG we were able to successfully meet the new requirements. As, most people are aware, Engineering Projects can be challenging due to technical issues that must be resolved. However, equally as challenging is being able to work and communicate effectively cross-functionally with other Departments including Quality, Manufacturing, Marketing, and upper Management. Chris performed well in all of these areas. At times, ERG became a natural extension of our Product Development Team and as a result, I was able to focus solely on other technical issues. Through challenging times, Chris was very personable and always maintained a Professional disposition. I highly recommend his services.

"ERG is currently Syntheon's primary source for automation. Chris and his team have continued to provide quality output on time and within budget. ERG is very responsive and accommodating."

Derek Deville VP of R&D Syntheon, LLC

Carlos Rivera VP of Operations Syntheon, LLC

Since 2011, ERG has provided us with state of the art infusion catheters that we have used in cutting edge research in bio-psychiatry, drug distribution monitoring, drug distribution prediction, and studies in intracranial hemorrhage treatment. ERG has provided us with rapid feedback to our technical questions and rapid turnarounds on our orders. Beyond catheters, ERG has worked with us to develop customized solutions for gaps in our neurosurgical procedures. We would not have achieved our success to date without ERG's partnership.

I'm personally very impressed with Chris' concepts and equipment designs. His enthusiasm that there is an engineering resolution for every customers problem is a very positive work philosophy. He is highly skilled at what he does.

Just wanted to offer my testimonial to the fine work Chris Ross and his firm have been doing for my Company, Precision Medical Devices Inc., on our groundbreaking technology. To date, Chris and his firm have consistently provided excellent, timely and cost-effective engineering solutions to assist us in upgrading our technology. I foresee a long and mutually satisfying business relationship between PMD and ERG.

That's why Fortune 1000 companies and world class hospitals trust ERG for their most complex projects.