Controls method is selected to appropriately meet the requirements of the project.

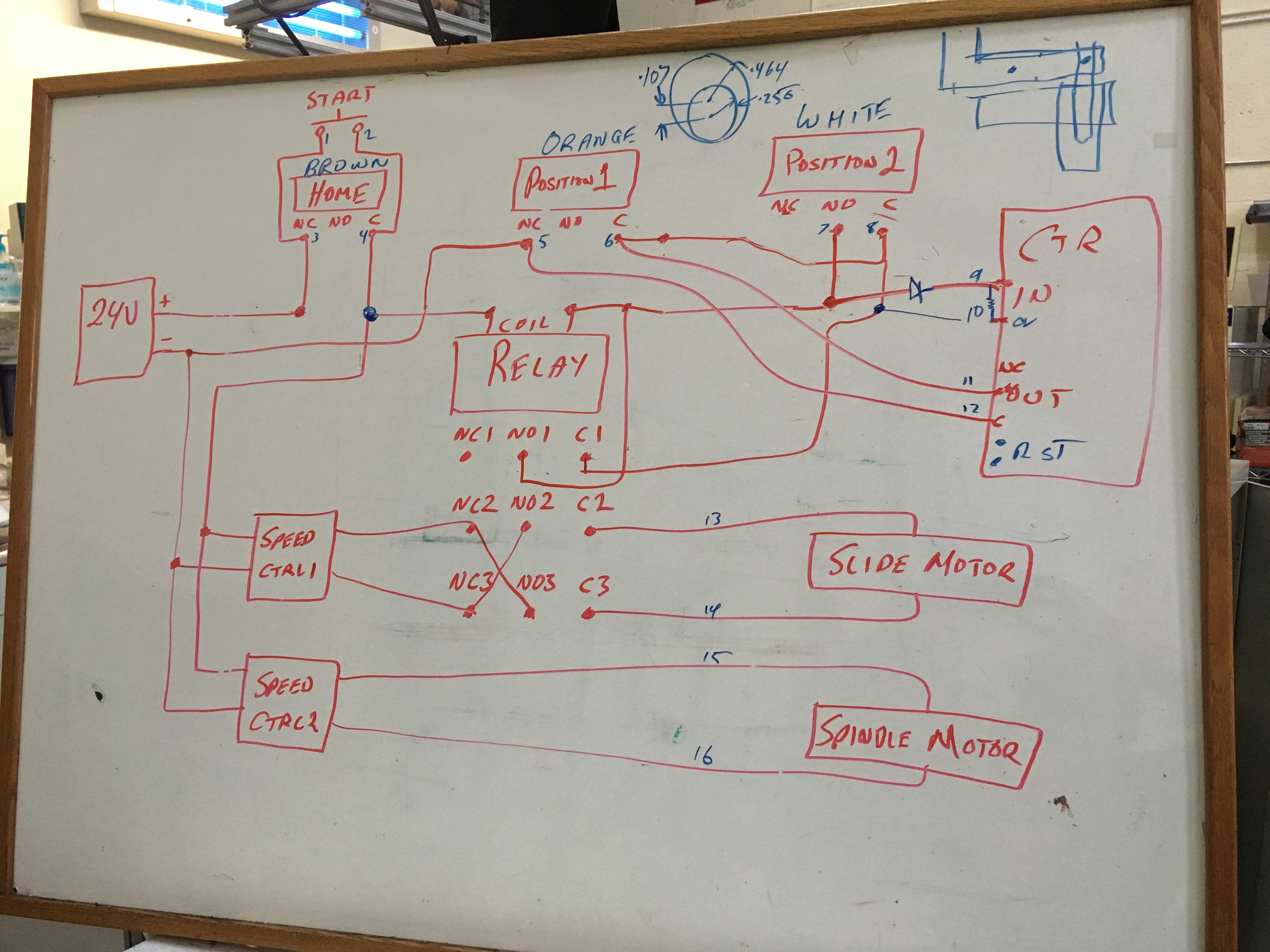

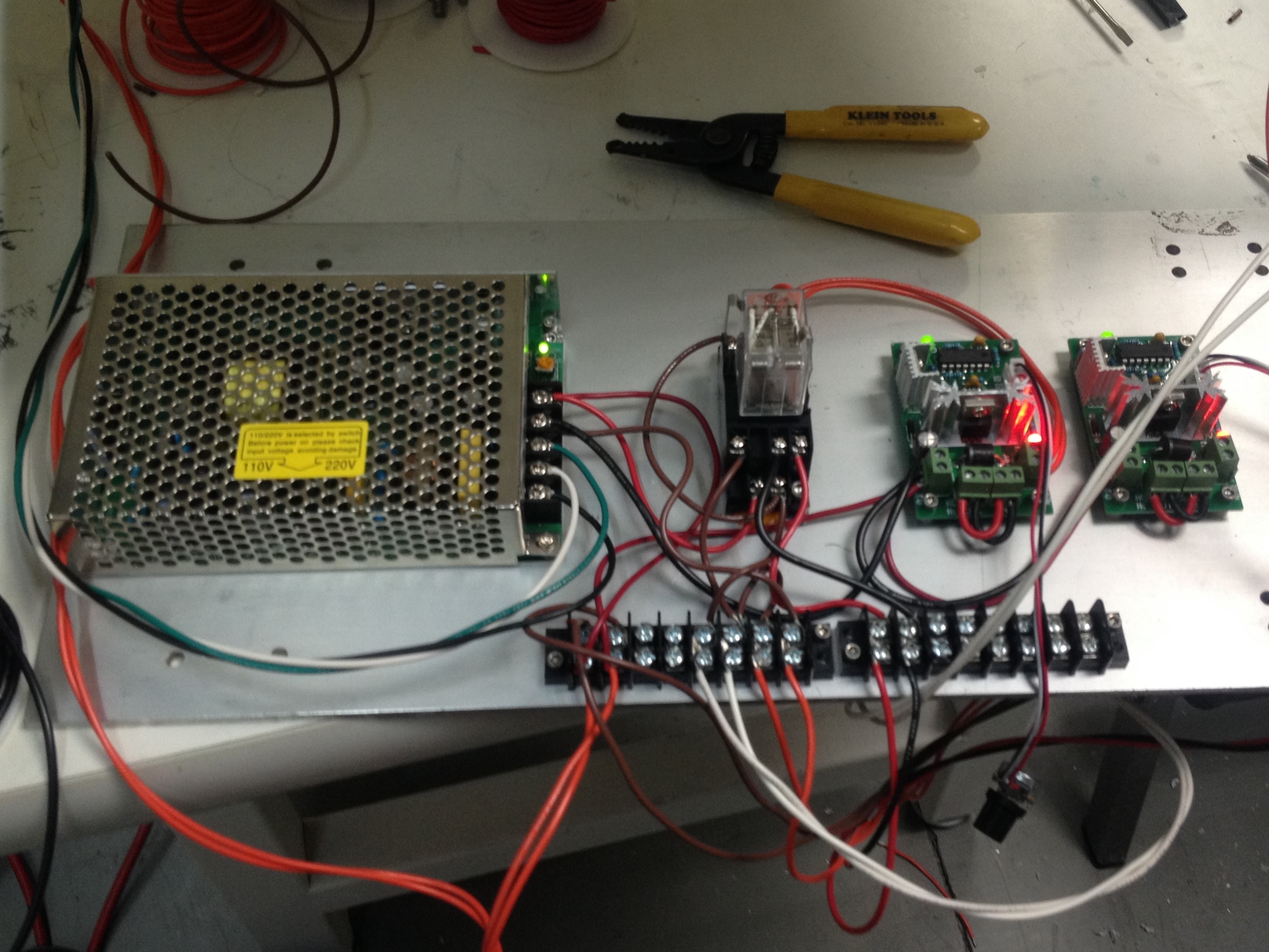

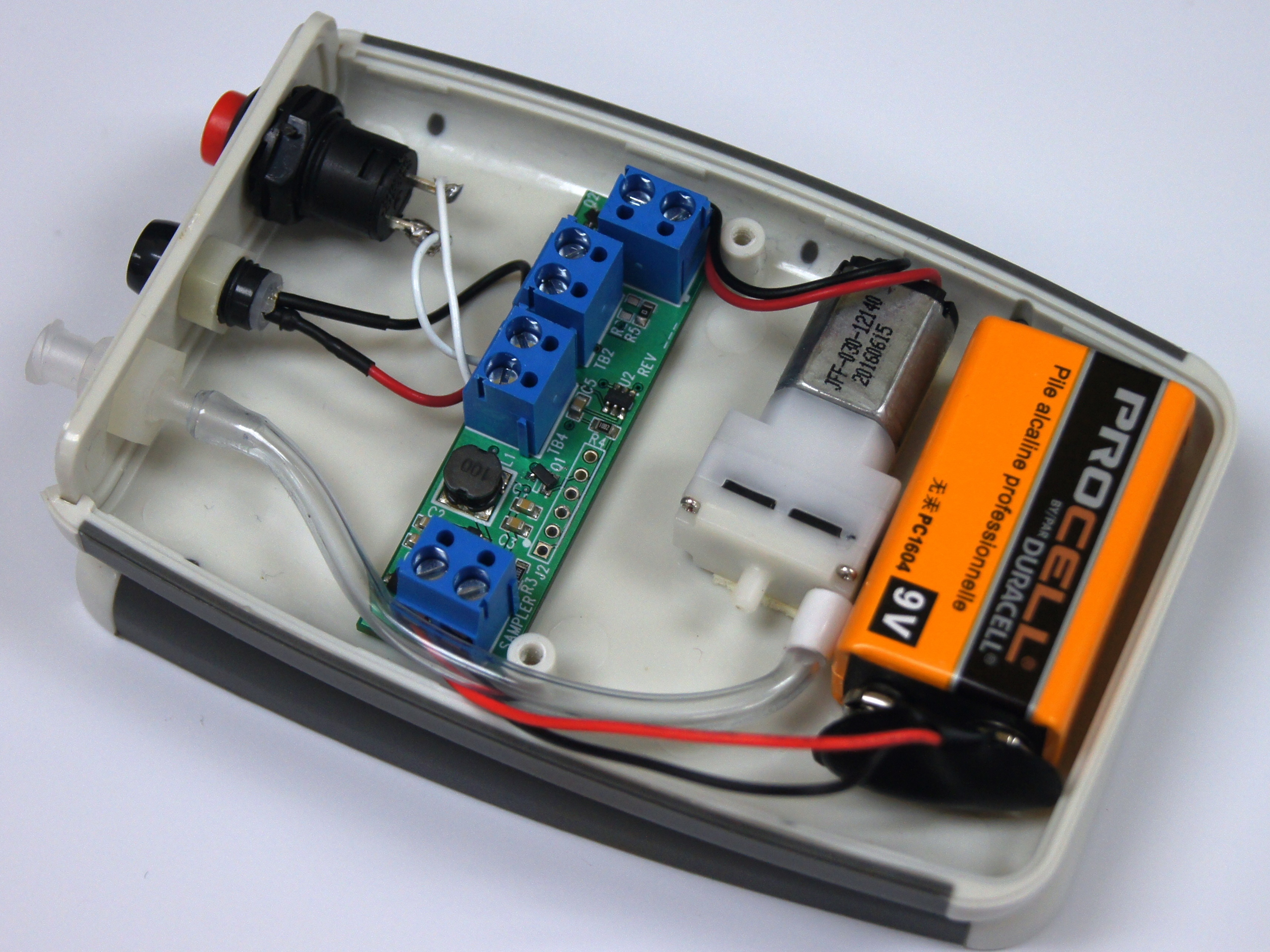

Reliable, repetitive electro-mechanical operation with no software to validate.

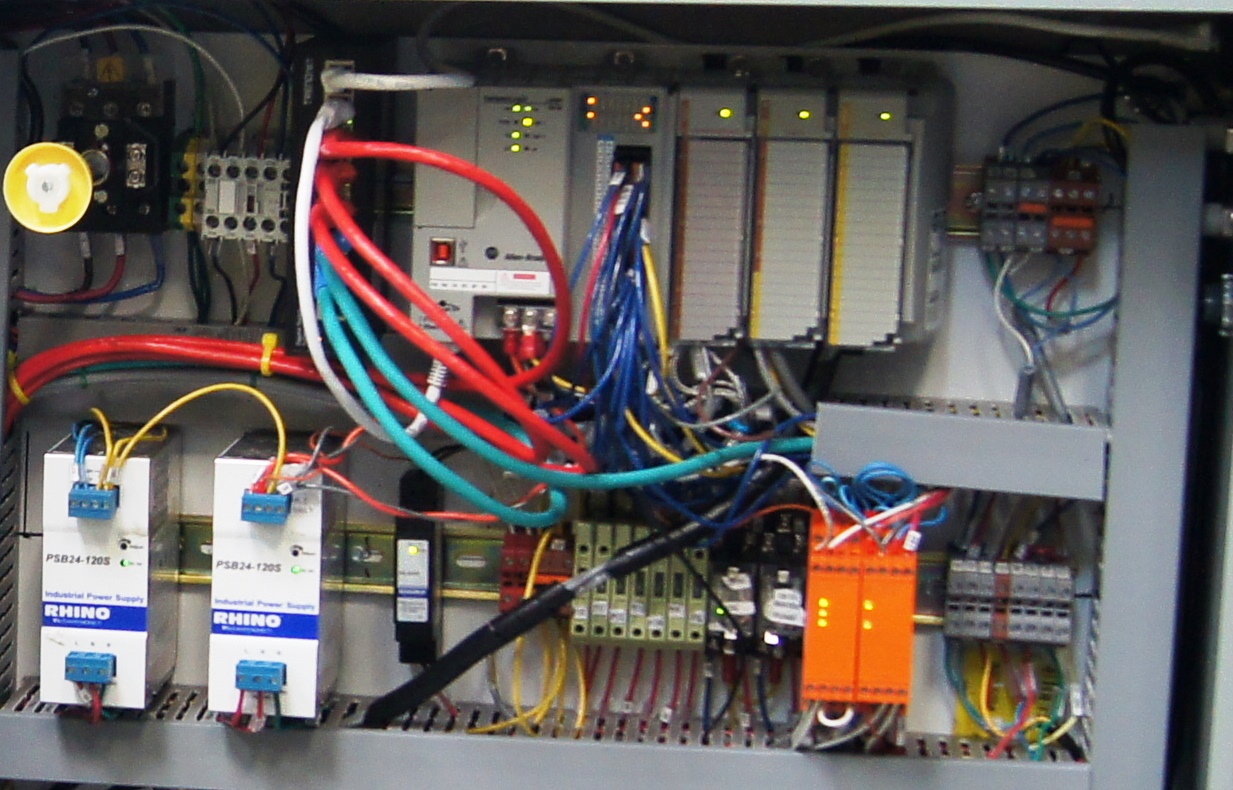

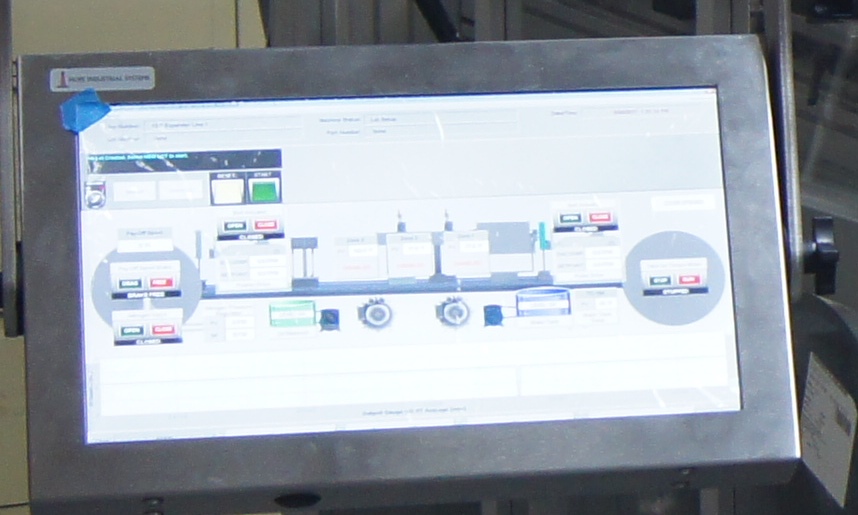

Rugged industrial digital computer used to control simple and complex machine operation. The system can be a 'black box' where all program parameters in the PLC code are fixed and inaccessible to the operator or through a Human Machine Interface (HMI), process parameters, tuning parameters, historical data and process recipes are fully accessible by operators with appropriate security credentials.

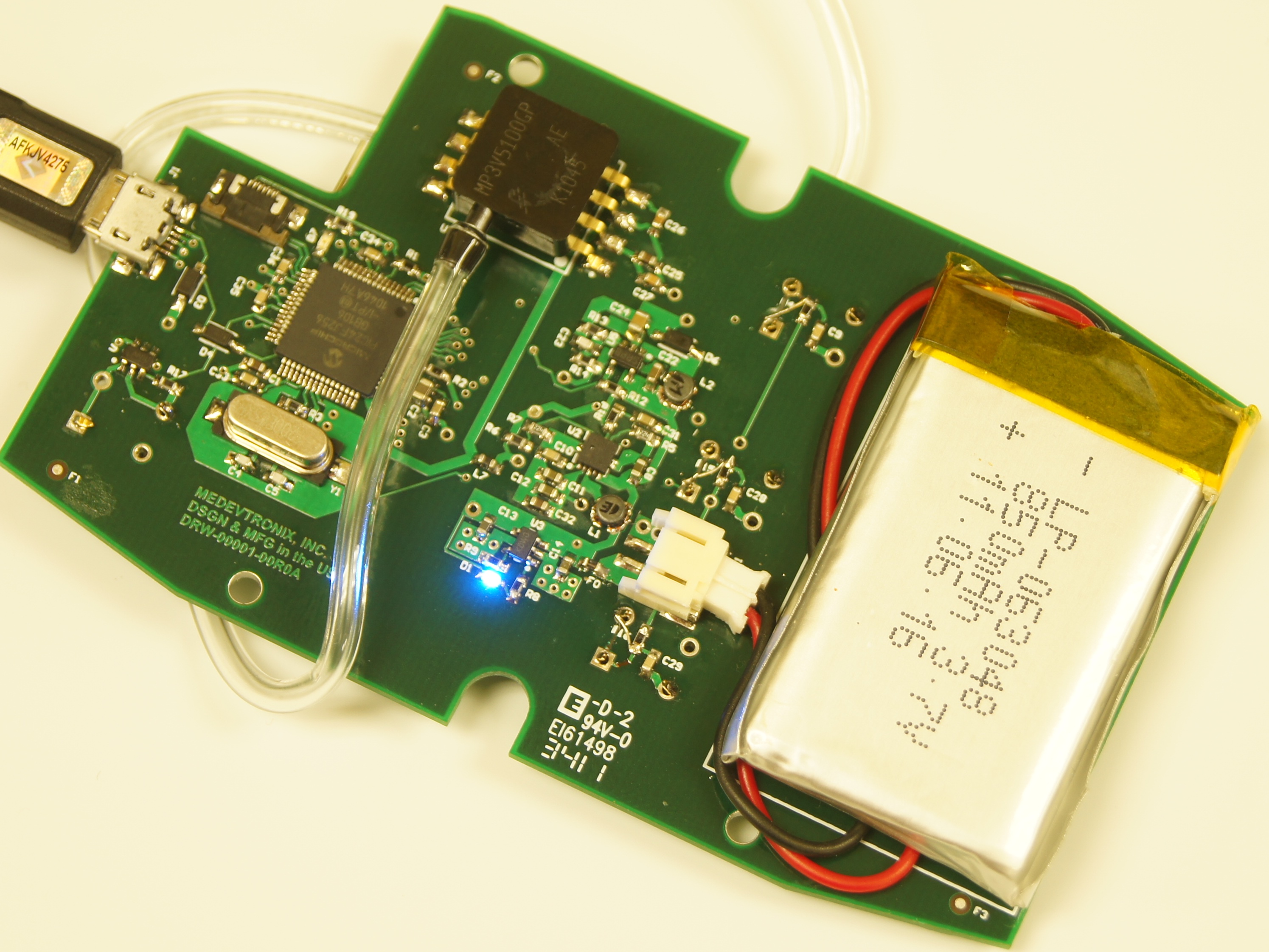

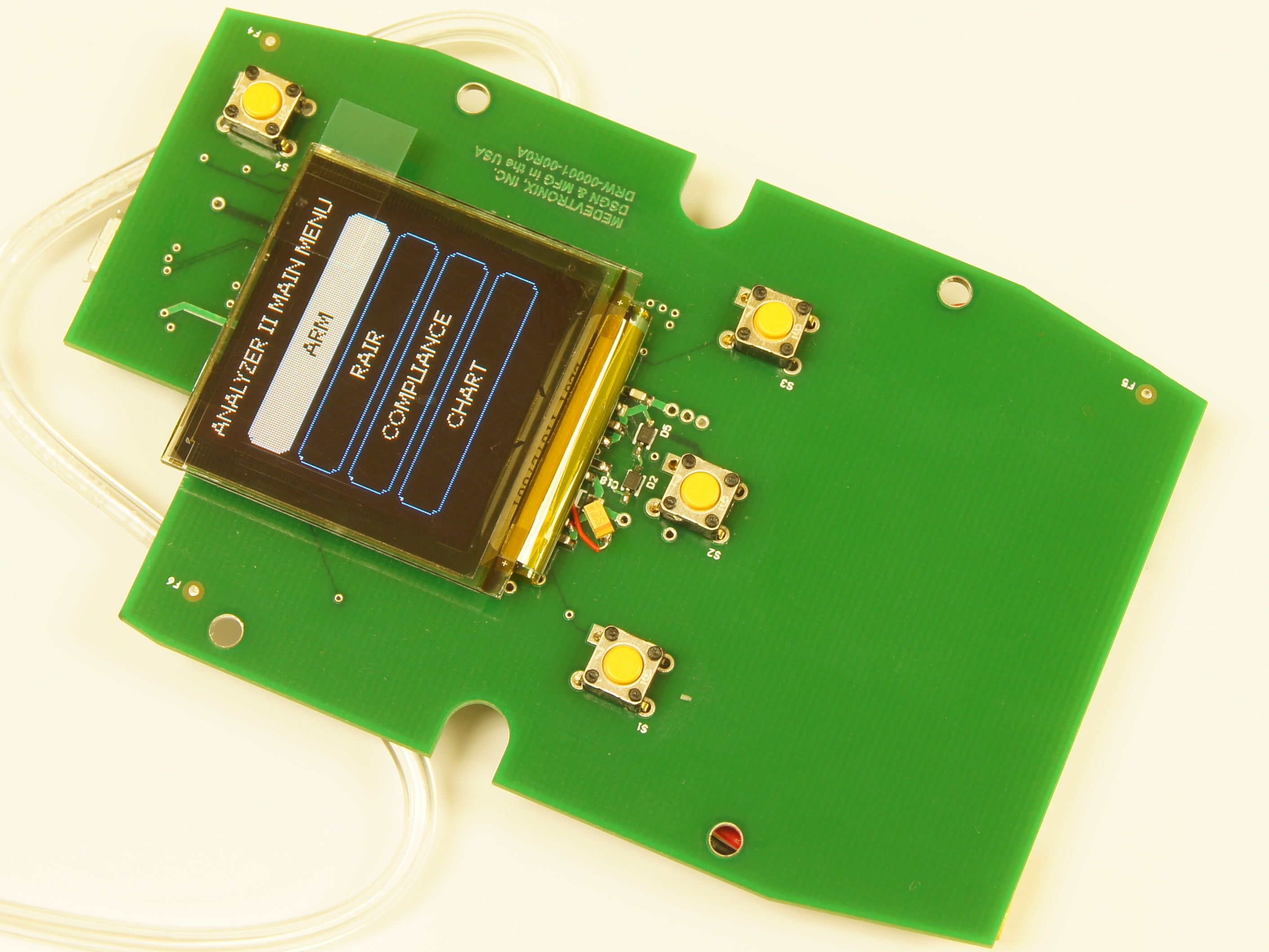

Microcontroller based systems for handheld devices and tools. Typically utilized in our product development operations rather than machinery and equipment.

Advanced process control not only for maintaining process conditions at setpoint but controlling one process parameter in response to different process measurement. Maintain output quality while controlling several interdependant process parameters.

Maximum flexibility, data collection and manipulation including intuitive flowcharting, powerful graphics tools, easy SQL interfacing and higher math functions and data types, PC control has the tools to easily handle complex applications.

That's why Fortune 1000 companies and world class hospitals trust ERG for their most complex projects.